Welflow Engineering

Welflow Engineering Welflow Engineering

Welflow Engineering

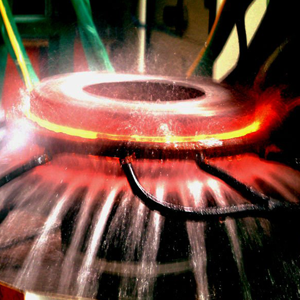

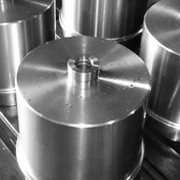

Ever since 1996, we at WelFlow Engineering Company have dedicated ourselves to providing best heat treatment services to our customers. Recognising the evolving need of our many customers we have introduced critical processes and upgraded our facilities with process equipments from companies renowned worldwide for latest technologies in Heat treatment processes and systems. We provide the maximum number of processes for castings and alloy steels at a single location. Having a total covered area of 24000 Sq. Ft. our heat treatment furnaces are well equipped for processes ranging from Stress relieving to Carbo nitriding, Induction Hardening and now Vacuum Heat Treatment.

We strive for complete customer satisfaction by continuous improvement of quality, efficiency and speed of all of our business activities. We work in consultation with our customers to innovate heat treatment processes to fulfill their exact requirements in a way that reduces cost and give quality results in a mutually decided time frame. Our unique methodology has won us tremendous customer good will and appreciation.

We have built a reputation for quality, timely delivery and excellent customer relationships. We are adequately equipped with testing and inspection facilities for alloy steels to ensure complete conformance to the heat treatment quality requirements of our renowned customers.

Welflow Engineering is a ISO 9001 - 2008 accredited company operating in commercial Heat treatment industry over a decade. We are also a member of American Society of Materials [ Heat Treatment ]. From our modest begining to date, we have continuously upgraded our vision and objectives keeping up with the pace of advancements in the heat treatment industry, both in terms of adopting new technologies as well as processes.

VISION

We at Welflow Engineering company are committed to provide quality heat treatment processes for total customer satisfaction is stipulated schedule by way of continual improvement in processes & technology.

OBJECTIVES

WORKFORCE

Our workforce consists of different teams who work in harmonization with each other. This ensures better execution & fulfillment of clients orders.

DIFFERENT TEAM THAT MAKE OUR WORK FORCE ARE

| Corporate Marketing | Process, Quality Systems, Technical |

|---|---|

| Nilesh Gohel | Dhruva Gohel |

| 9822537180 | 9371312455 |