Welflow Engineering

Welflow Engineering Welflow Engineering

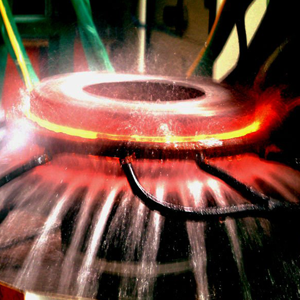

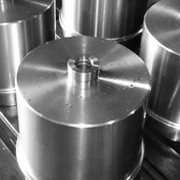

Welflow EngineeringWelFlow Engineering is proud to introduce INDUCTION HARDENING, our latest and state of the art equipment in surface hardening technologies.

A widely used process for the surface hardening of steel !

The components are heated by means of an alternating magnetic field to a temperature within or above the ransformation range followed by immediate quenching.

The core of the component remains unaffected by the treatment and its physical properties are those of the bar from which it was machined, whilst the hardness of the case can be within the range 37/58 HRC.

Carbon and alloy steels with an equivalent carbon content in the range 0.40/0.45% are most suitable for this process.This operation is most commonly used in steel alloys.

Many mechanical parts, such as shafts, gears, springs, etc. are subjected to surface treatments, before the delivering, in order to improve wear behavior.

The effectiveness of these treatments depends both on surface materials properties modification and on the introduction of residual stress.

Among these treatments, induction hardening is one of the most widely employed method to improve component durability.

It determines in the work-piece a tough core with tensile residual stresses and a hard surface layer with comessive stress, in the surface layer.

Features of the Induction Hardening Process

Resulting in

The Equipment manufactured by Induction Equipment India is a company belonging to SAET Group of Italy, is a leading manufacture of Induction Heating and Hardening Equipment in India, offering state-of the art features and configurations to international standards. It is now now our global partner for Induction Hardening. We have installed a Single station Vertical Induction

Hardening Machine. Shafts upto a length of 1500mm and diameters upto 400 mm can be induction hardened upto a case depth ranging from 1.5 mm to 5mm. The Single station vertical scan machine is a highly versatile equipment. With various types of Power Sources and machine configurations, these could be used for hardening practically any type of component used in automobile and earth moving equipment manufacturing,engineering industry textile machines manufacturing, defence production etc.

Applications

Ever Since 1996, we at WelFlow Engineering Company have dedicated ourselves to providing best heat treatment services to our customers. Recognizing the evolving need of our many customers, we have introduced critical processes and upgraded our facilities with process equipments from companies renowned worldwide for latest technologies in Heatreatment processes and systems. . We have evolved as a full fledged heat treatment company in Satara. We provide the maximum number of processes for castings and alloy steels at a single location. Having a total covered area of 24000 Sq. Ft. our heat treatment furnaces are well equipped for processes ranging from Stress relieving to Carbo nitriding, Induction Hardening and now Vacuum Heat Treatment.

We strive for complete customer satisfaction by continuous improvement of quality, efficiency and speed of all of our business activities. We work in consultation with our customers to innovate heat treatment processes to fulfill their exact requirements in a way that reduces cost and give quality results in a mutually decided time frame. Our unique methodology has won us tremendous customer goodwill and appreciation.

We have built a reputation for quality, timely delivery and excellent customer relationships. We are adequately equipped with testing and inspection facilities for alloy steels to ensure complete conformance to the heat treatment quality requirements of our renowned customers.

Welflow Engineering is a ISO 9001 - 2008 accredited company operating in commercial Heat treatment industry over a decade. We are also a member of American Society of Materials [ Heat Treatment ]. From our modest begining to date, we have continuously upgraded our vision and objectives keeping up with the pace of advancements in the heat treatment industry, both in terms of adopting new technologies as well as processes.

VISION

We at Welflow Engineering company are committed to provide quality heat treatment processes for total customer satisfaction is stipulated schedule by way of continual improvement in processes & technology.

OBJECTIVES

WORKFORCE

Our workforce consists of different teams who work in harmonization with each other. This ensures better execution & fulfillment of clients orders.

DIFFERENT TEAM THAT MAKE OUR WORK FORCE ARE

| Corporate Marketing | Process, Quality Systems, Technical |

|---|---|

| Nilesh Gohel | Dhruva Gohel |

| 9822537180 | 9371312455 |