Welflow Engineering

Welflow Engineering Welflow Engineering

Welflow EngineeringFor Alloy steels

For castings

Annealing

Annealing is a generic term denoting a thermal process of heating to and

at a suitable temperature followed by cooling at an appropriate rate primarily

for purpose of softening the metallic materials. . Annealing is carried out for

further cold work, machining or to improve electrical properties. The choice of

process , cycle and furnace equipment depends upon material, chemical

composition, prior thermal history, property and surface quality requirements

after processing. In practice, there are different thermal cycles for steel to

achieve various goals of annealing. These cycles fall into different categories

that can be classified according to the temperature temperature to which the

steel is heated and method cooling is used. Few common annealing practices

are 'Full annealing', 'Subcritical annealing', 'Spheroidised annealing', 'Intercritical

annealing', 'Isothermal Annealing' Annealing' and special processes like

Decarburisation annealing etc.

Stress Relieving

Stress Relieving treatment is used to remove stresses residual from other

manufacturing steps. The treatment involves controlled heating to a temperature

below lower critical temperature, holding for sufficient time and cooling slowly

to avoid the introduction of thermal stresses. . It should be noted that the

residual stresses couldn't be totally eliminated and reduced to zero. Higher

residual stresses and rapid heating during subsequent heat-treating operations

(such as hardening) can lead to distortion of the parts.

Normalising

Normailising is a heat treatment process involving heating a ferrous alloy to the

austenitising temperature and air cooling to a temperature significantly below

the transformation range. Normailising is mainly applied to unalloyed or low

alloyed steels. This process refines the grains of the steel that has become

coarse in the prior thermal cycling such as hot forging and welding. This grain

refinement improves machinability and enhances better response in subsequent

heat treatment . In normalising process cooling rate after austenisation is an

important factor. Plain unalloyed low carbon steel may be transformed to fine

pearlite and ferrite structure after normalising process under certain cooling

rate. But low alloyed steels may have bainite and fine pearlite that increases

hardness and reduces machinability. Controlled atmosphere heating with

controlled cooling can be done in continuous normalising furnace with specially

designed various cool section after hot zone, the hardness of the normalised parts

designed can be maintained within a close band that improve productivity in

machining and consistency of machined part dimensions.

Case Hardening

A generic term covering various processes that are applicable to the steel that

changes the chemical composition of the surface by thermo-chemical diffusion

processes forming a case. . The diffusion process sets up a chemical gradient

that reflects as a hardness gradient. The processes commonly used are

'Carburising', 'Nitriding', 'Carbonitriding', 'Cyaniding', 'Nitrocarburising'. The

depth of the case depth upon the process completion time, environment

concatenation levels like carbon potential, Nitrogen potential etc. and the

material's chemical composition.

Ferritic Nitrocarburising

This process is a thermochemical treatment that involves diffusional addition of

nitrogen and carbon. This process is generally done at temperatures below 580°C

(1076°F) and usually for 3 hours. It is also called 'short nitriding process'. The

essential difference between nitriding and nitrocarburising is that in nitro

carburising, the surface compound layer contributes for improved properties while

the diffused nitrogen layer is important in nitriding process. All ferrous alloys can be

ferritic nitro carburised while only nitrodable steels containing Al, Cr, Mo can be used

for nitriding process. The process is done in an atmosphere containing NH3 and a

carbon donor such as LP gas, CO2 or Propane at temperatures below 580°C

(1076°F). The ferrous material after nitrocarburising need not be quenched if

surface hardness is the only consideration. However if the steel after the process is

quenched in oil or water, nitrogen is retained in solution in the diffusion zone which

contribute for improved fatigue life.

Hardness after Ferritic Nitrocarburising of few ferrous alloys is as follows.

| HV.2 | |

|---|---|

| Carbon steels | 450 |

| Low alloy steels | 700 |

| Tool & die steels | 1000 |

| Corrosion & heat resistant steels | 900 |

| Ductile malleable & grey casting | 600 |

Nitriding

Nitriding is the process of saturating the surface of the steel with nitrogen.

Saturation is accomplished in an atmosphere of ammonia gas (NH3) at

temperatures ranging 480°C (896°F) to 580°C (1076°F). Ammonia dissociate to

nascent nitrogen and hydrogen when in contact with the hot jobs 2NH3®2N +

3H2. Atomic nitrogen formed diffuses into alpha iron and saturate the metal.

Nitrided steel acquire high hardness and retain the hardness even after

subsequent heating to 600°C (1112°F). Nitriding increases wear resistance,

fatigue and corrosion resistance. Nitriding is usually applied to medium carbon and

alloy steels containing carbon and alloy steels containing aluminium, chromine,

molybdenum and other elements that are capable of forming nitrides since the

process is done at lower temperature, the time cycle will be longer than the

caburising cycle. It is preferable to harden and temper the parts prior to nitriding to

achieve best properties. The tempering temperature should be minimum of 20°C

(68°F) to 30°C (86°F) more thus the nitriding temperature to retain the core

properties. The nitrided depth usually between 0.2mm to 0.4mm. No quenching is

required as high hardness is obtained directly after this process.

Carbonitriding

In Carbonitriding, ammonia (NH3) is introduced into the carburising atmosphere

Ammonia decomposes at carburising temperatures and the steel absorbs the

atomic nitrogen. In this process both carbon and nitrogen are diffused together.

The essential advantage of nitrogen diffusion is that the case has better

hardenability Nitrogen as an austenite stabiliser, reduces the diffusion controlled

transformation of austenite to ferrite and pearlite. This higher hardenability allows

better control on hardness profiles, use of milder quenchants with lesser distortion.

Further this martensite containing Carbon-Nitrogen has better tempering behaviour.

Carbonitriding is generally performed at lower temperatures in the range of 815°C

(1499°F)-900°C (1652°F). Carbonitriding at higher temperatures (more than

900°C (1652°F)) can cause increased retained austenite and even porosity at skin

due to higher nitrogen activity. This process is generally restricted to produce case

depths below 0.7 mm.

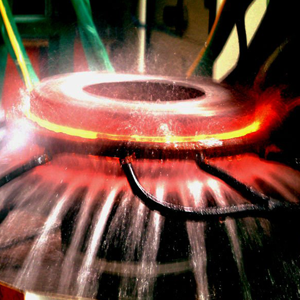

Vacuum Heat treatment

The Vacuum Heat Treatment Process is an advanced, energy-efficient and environmentally friendly. The furnace is equipped with Low Pressure Carburising facility. Digitally controlled flowmeters enable precise carburising gases to be released for accurate carbon diffusion and boost cycles. A variety of chromium, vanadium and Molybdenum alloy steels are most suitably hardened and tempered in a high pressure gas quench chamber of the furnace. A fully automatic sequencing amnd control of the process results in a highly uniform surface hardness and microstructure. It is proven that distortion of jobs is far less in a vacumm heatreatment furnace than in any conventional heattreatment processes.Our furnace is a proven vacuum heat treatment equipment from SecoWarwick Allied with guaranteed process technology.

Wel Flow Engineering Company is a pioneer in providing heat treatment services to the industry since 1996. We have evolved as a full fledged heat treatment company in Satara. We provide the maximum number of processes for castings and alloy steels at a single location. Having a total covered area of 16000 Sq. Ft. our heat treatment furnaces are well equipped for processes ranging from Stress relieving to Carbo nitriding.

We strive for complete customer satisfaction by continuous improvement of quality, efficiency and speed of all of our business activities. We work in consultation with our customers to innovate heat treatment processes to fulfill their exact requirements in a way that reduces cost and give quality results in a mutually decided time frame. Our unique methodology has won us tremendous customer good will and appreciation.

We have built a reputation for quality, timely delivery and excellent customer relationships. We are adequately equipped with testing and inspection facilities for alloy steels to ensure complete conformance to the heat treatment quality requirements of our renowned customers.

Welflow Engineering is a ISO 9001 - 2008 accredited company operating in commercial Heat treatment industry over a decade. We are also a member of American Society of Materials [ Heat Treatment ]. From our modest begining to date, we have continuously upgraded our vision and objectives keeping up with the pace of advancements in the heat treatment industry, both in terms of adopting new technologies as well as processes.

VISION

We at Welflow Engineering company are committed to provide quality heat treatment processes for total customer satisfaction is stipulated schedule by way of continual improvement in processes & technology.

OBJECTIVES

WORKFORCE

Our workforce consists of different teams who work in harmonization with each other. This ensures better execution & fulfillment of clients orders.

DIFFERENT TEAM THAT MAKE OUR WORK FORCE ARE

| Corporate Marketing | Process, Quality Systems, Technical |

|---|---|

| Nilesh Gohel | Dhruva Gohel |

| 9822537180 | 9371312455 |